-

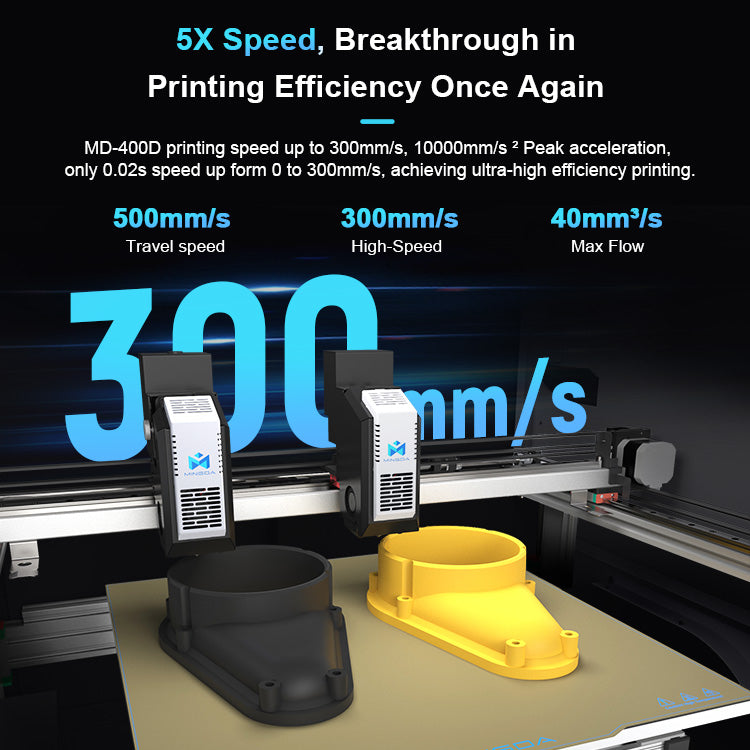

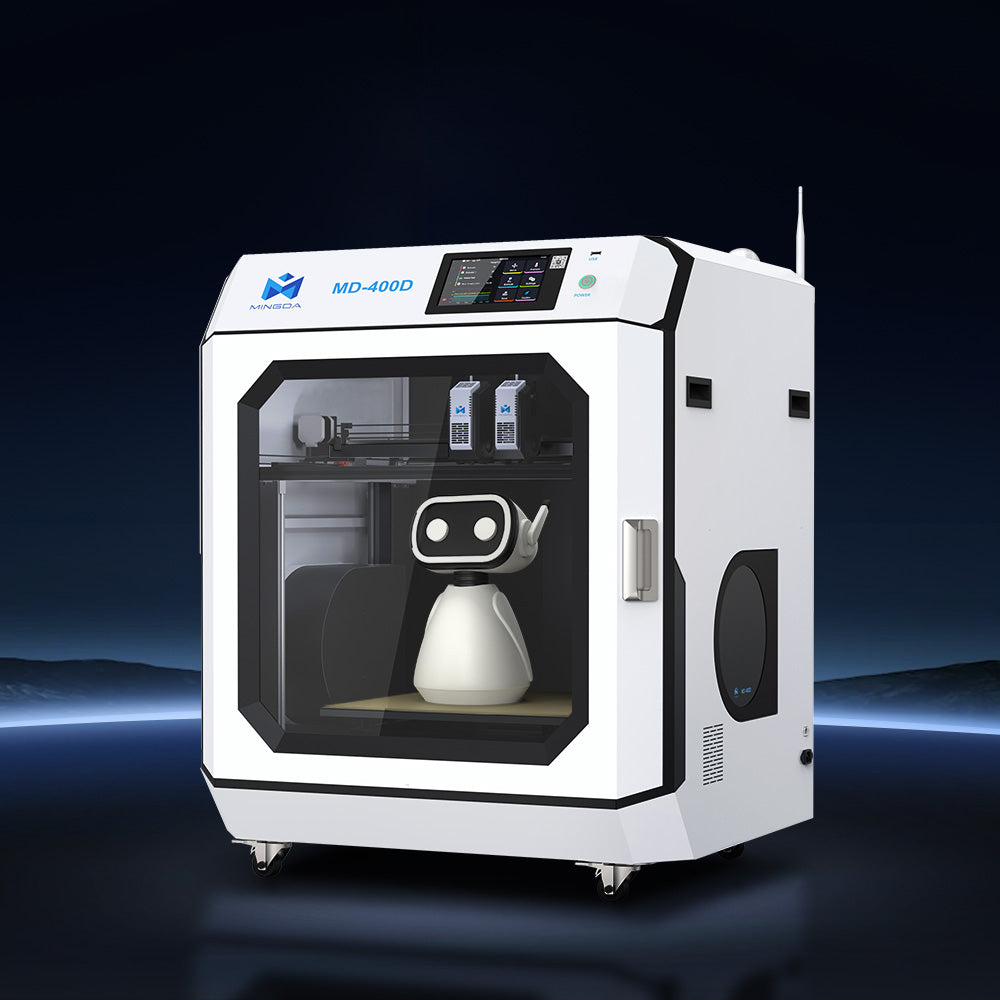

5X Speed, Breakthrough in Printing Efficiency Once Again

MD-400D printing speed up to 300mm/s, 10000mm/s ² Peak acceleration, only 0.02s speed up form 0 to 300mm/s, achieving ultra-high efficiency printing.

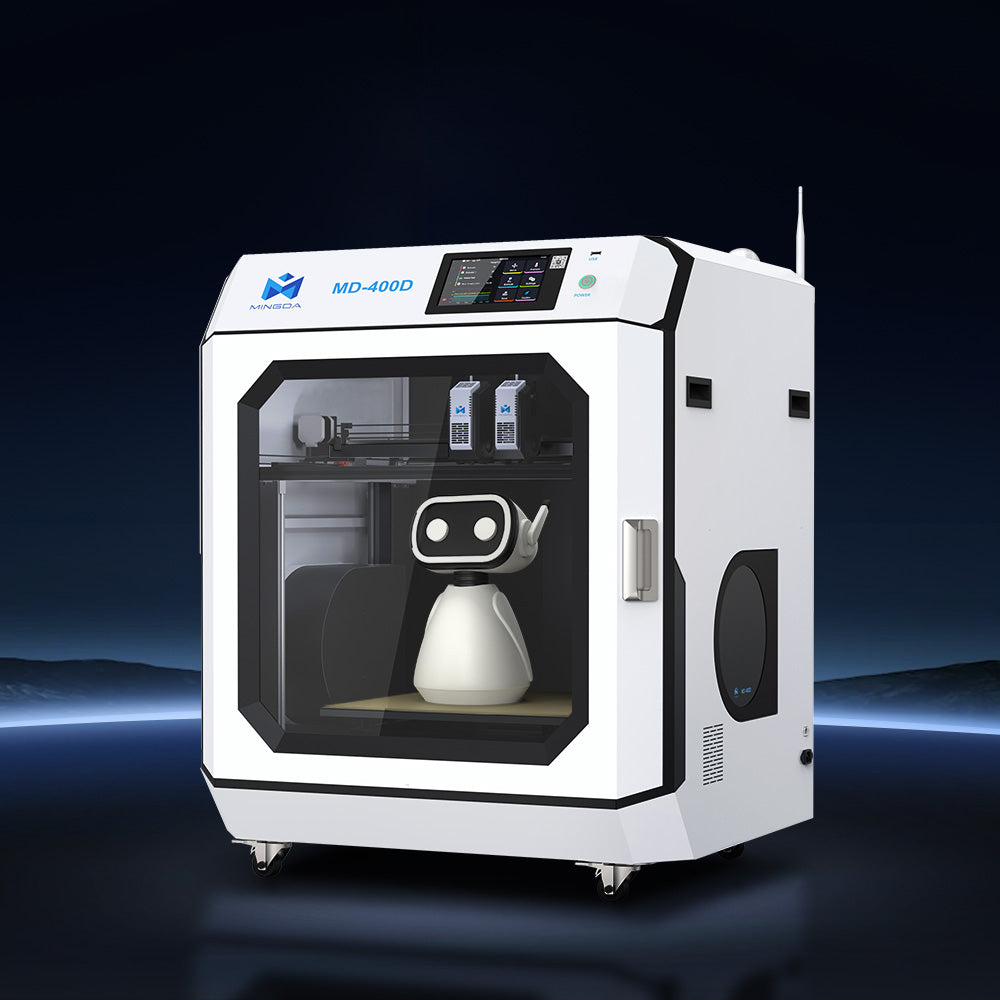

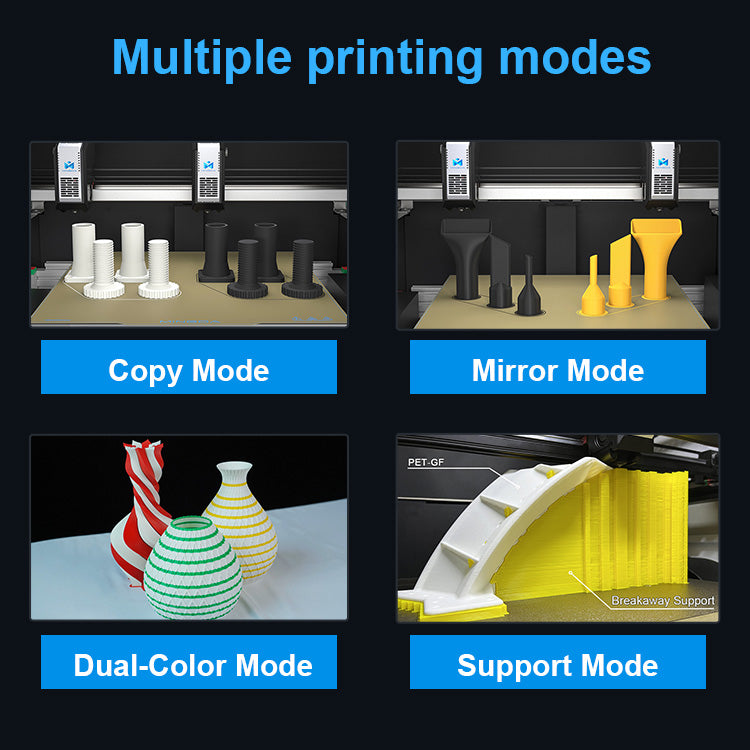

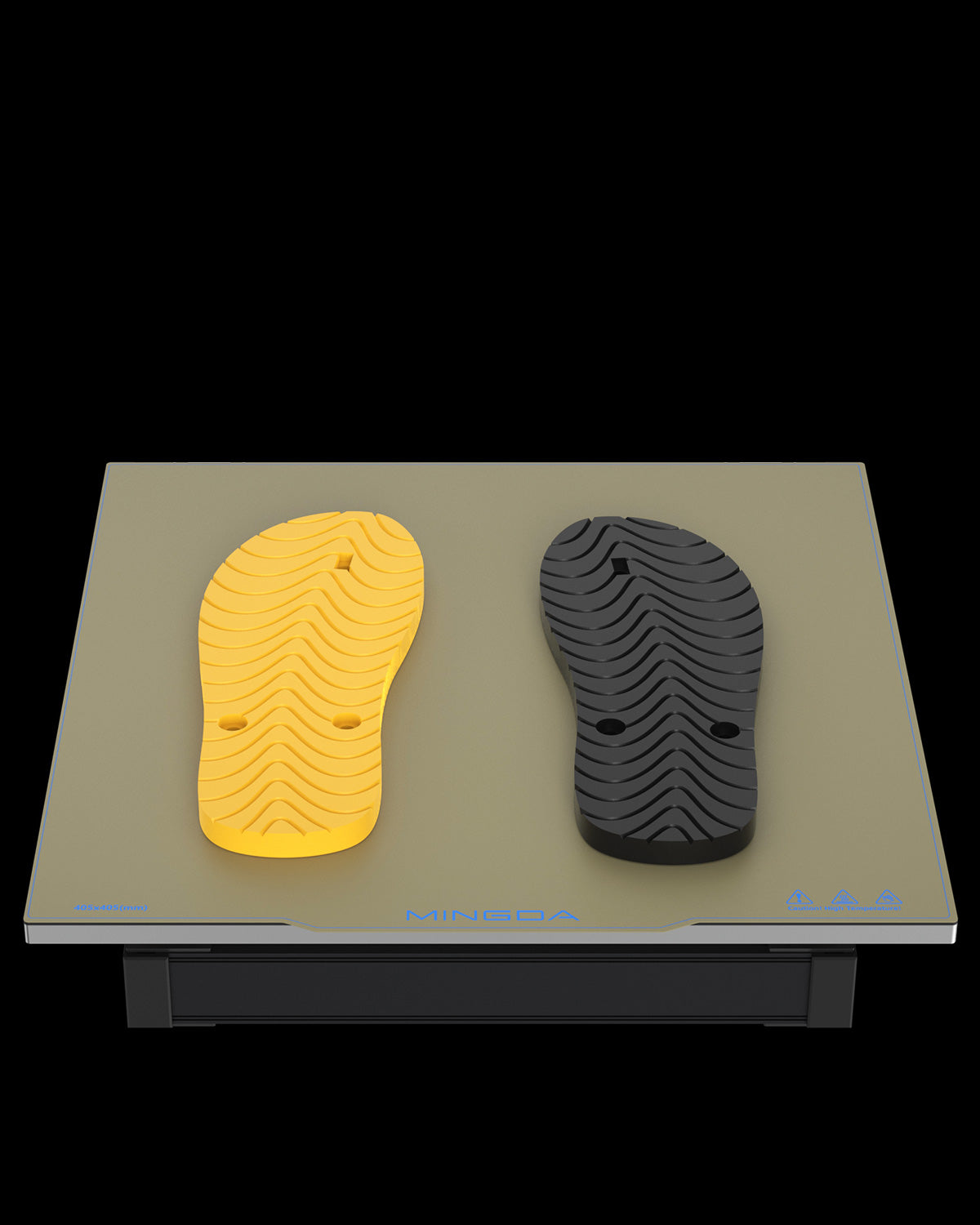

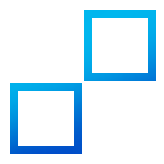

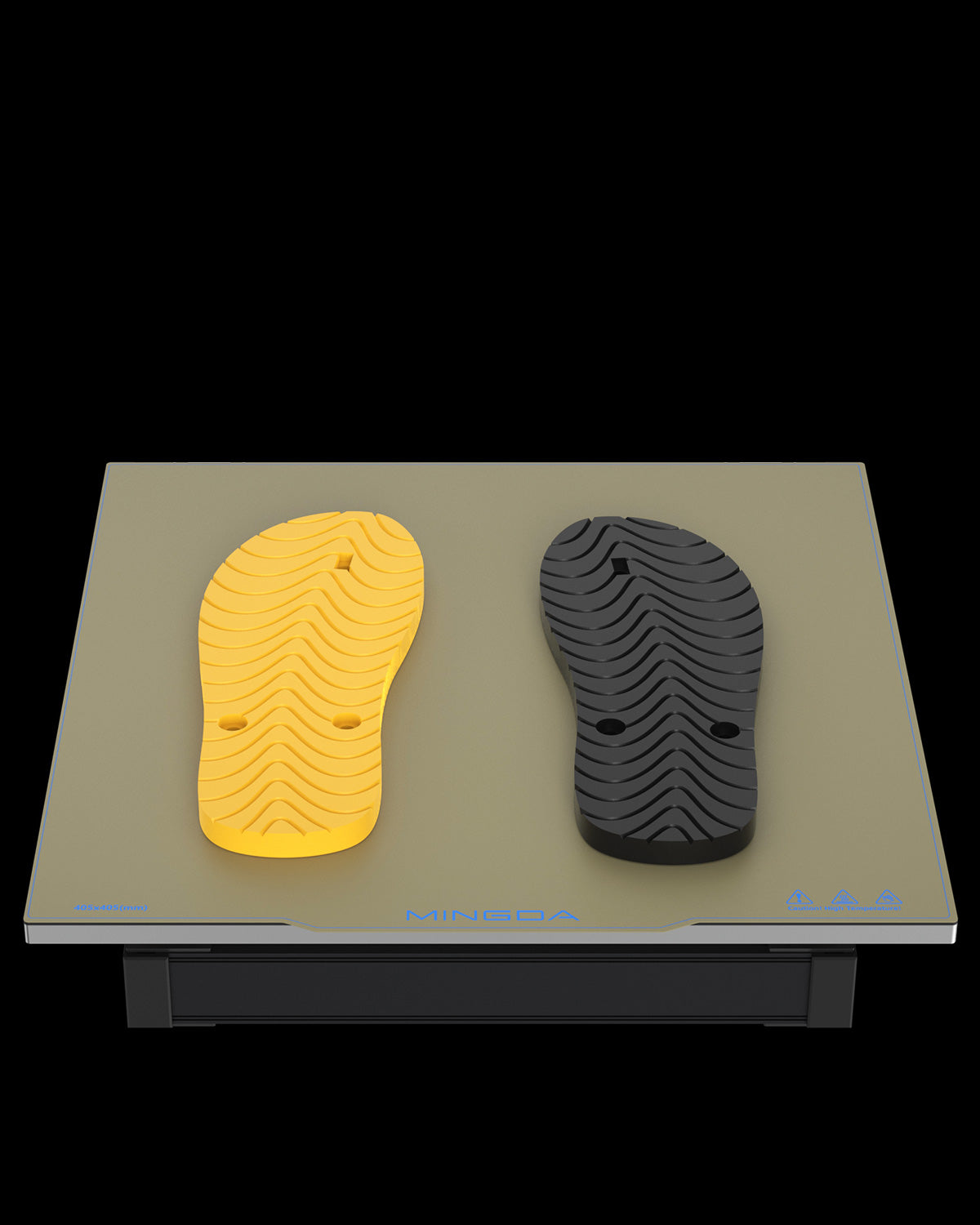

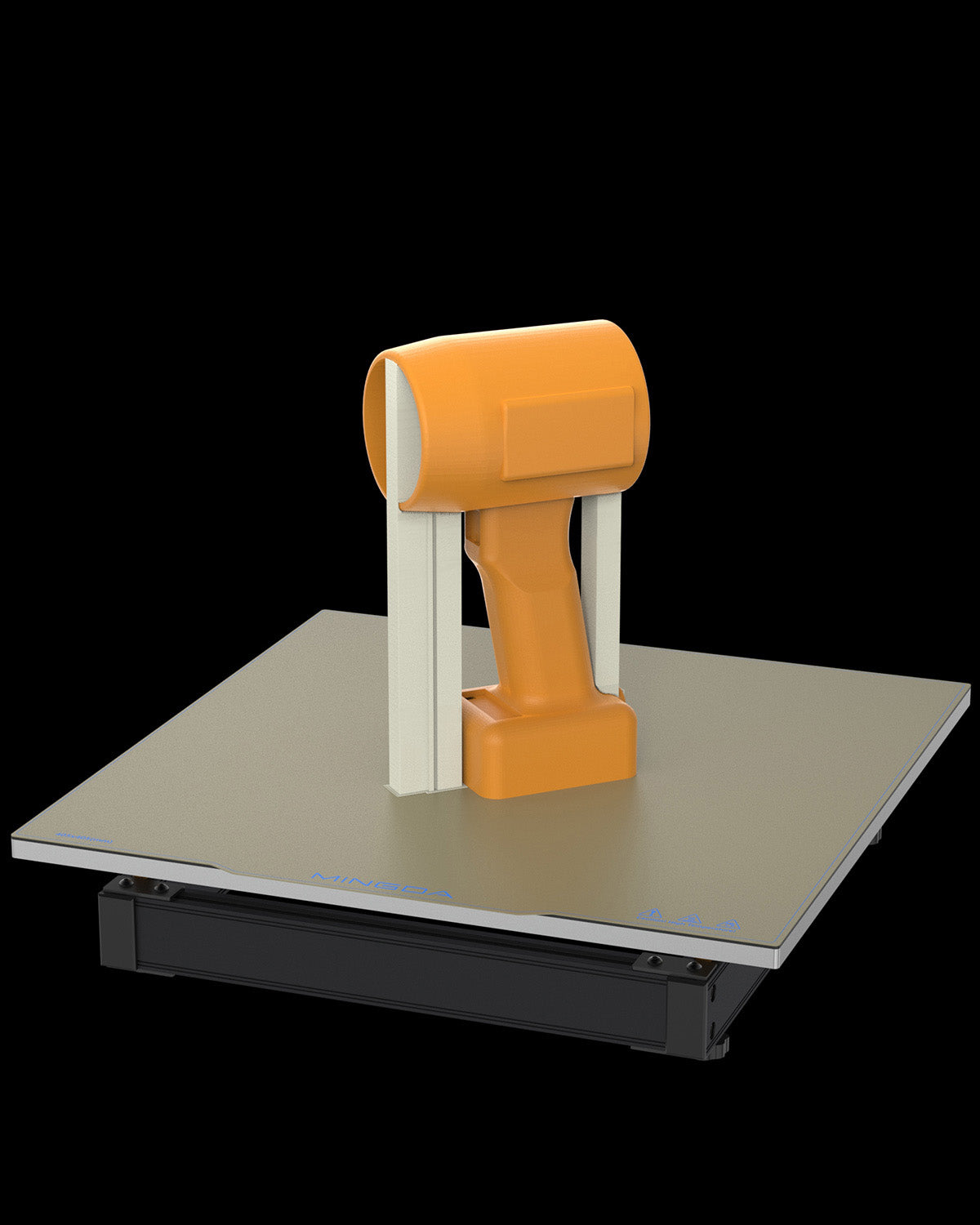

Infinite Possibilities with IDEX

IDEX in Dual-material Printing

Compared with a multi-material unit, IDEX dual-material printing requires less time in filament changing and creates less waste. Plus, IDEX offers the cleanest two-extruder solution that prevents cross-contamination. It creates a clean interface between two materials, embracing hassle-free removal and avoiding stains and weird blending along the seam.

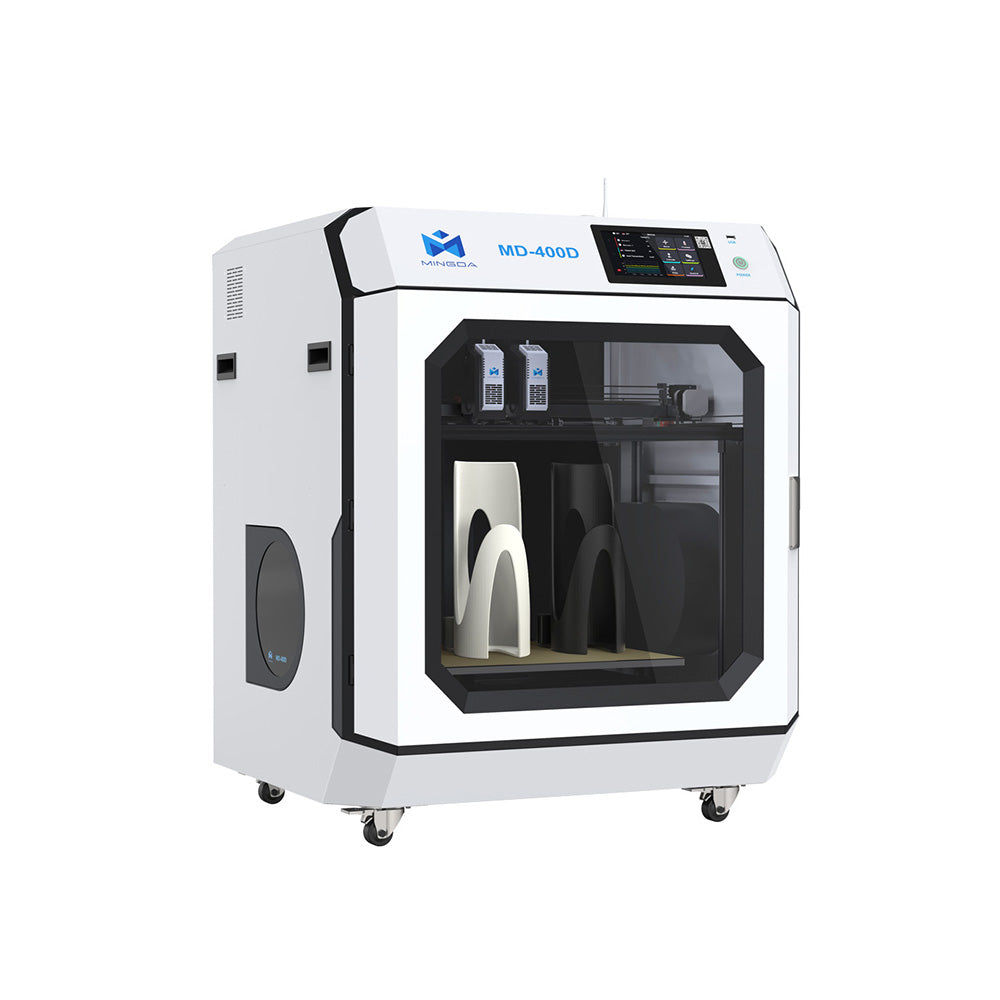

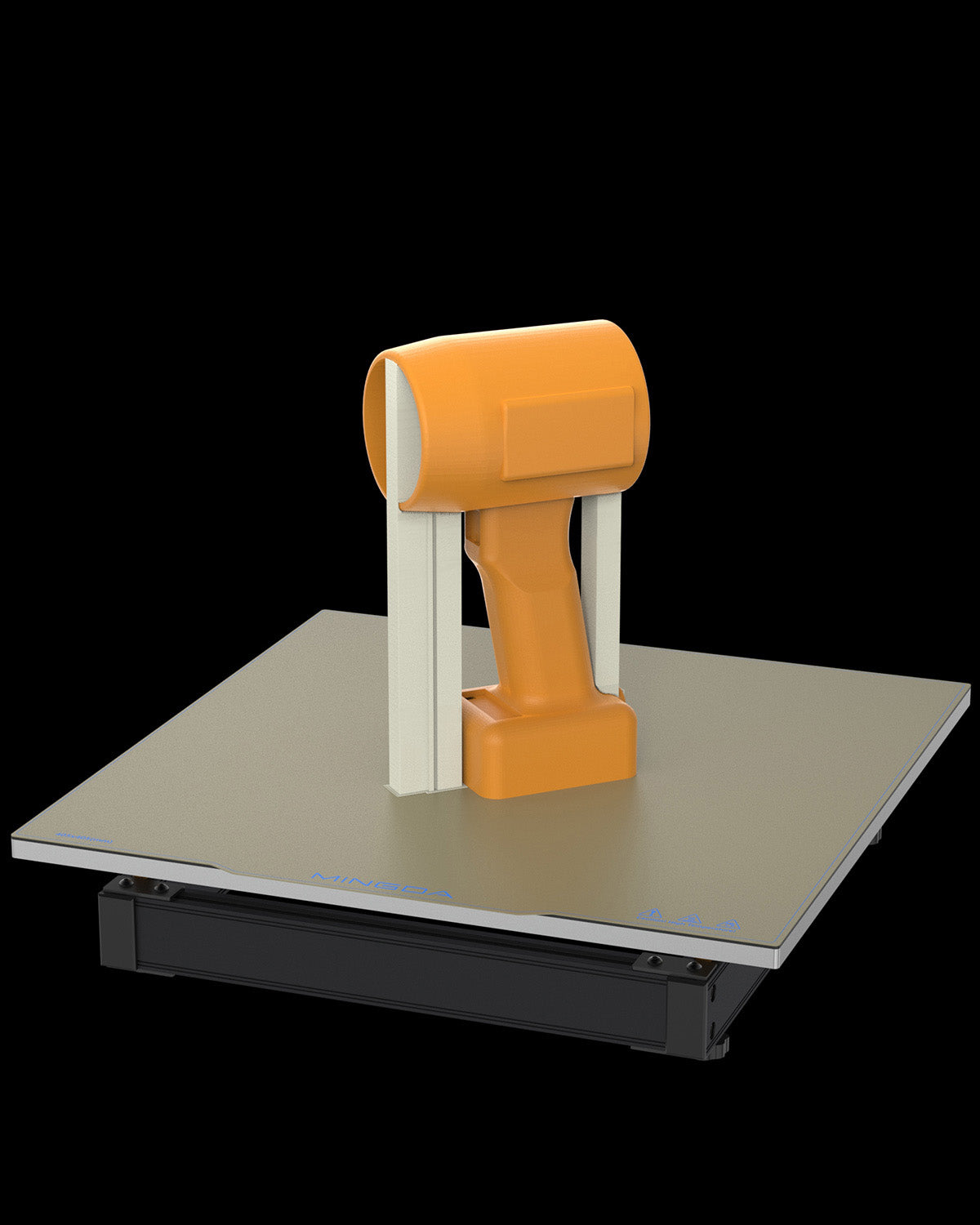

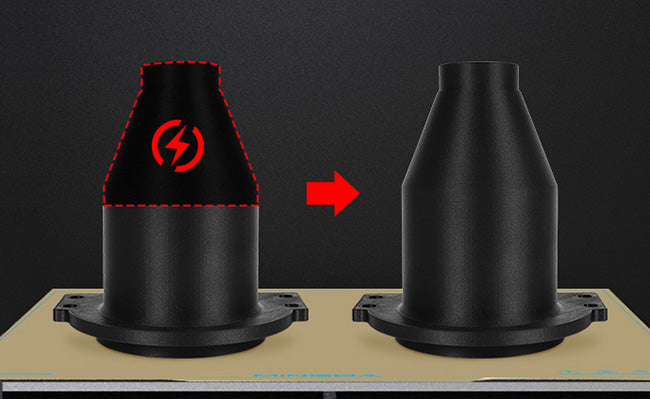

Breakaway Support Filament

Much easier to remove the support, the supported surface comes out clean and smooth.

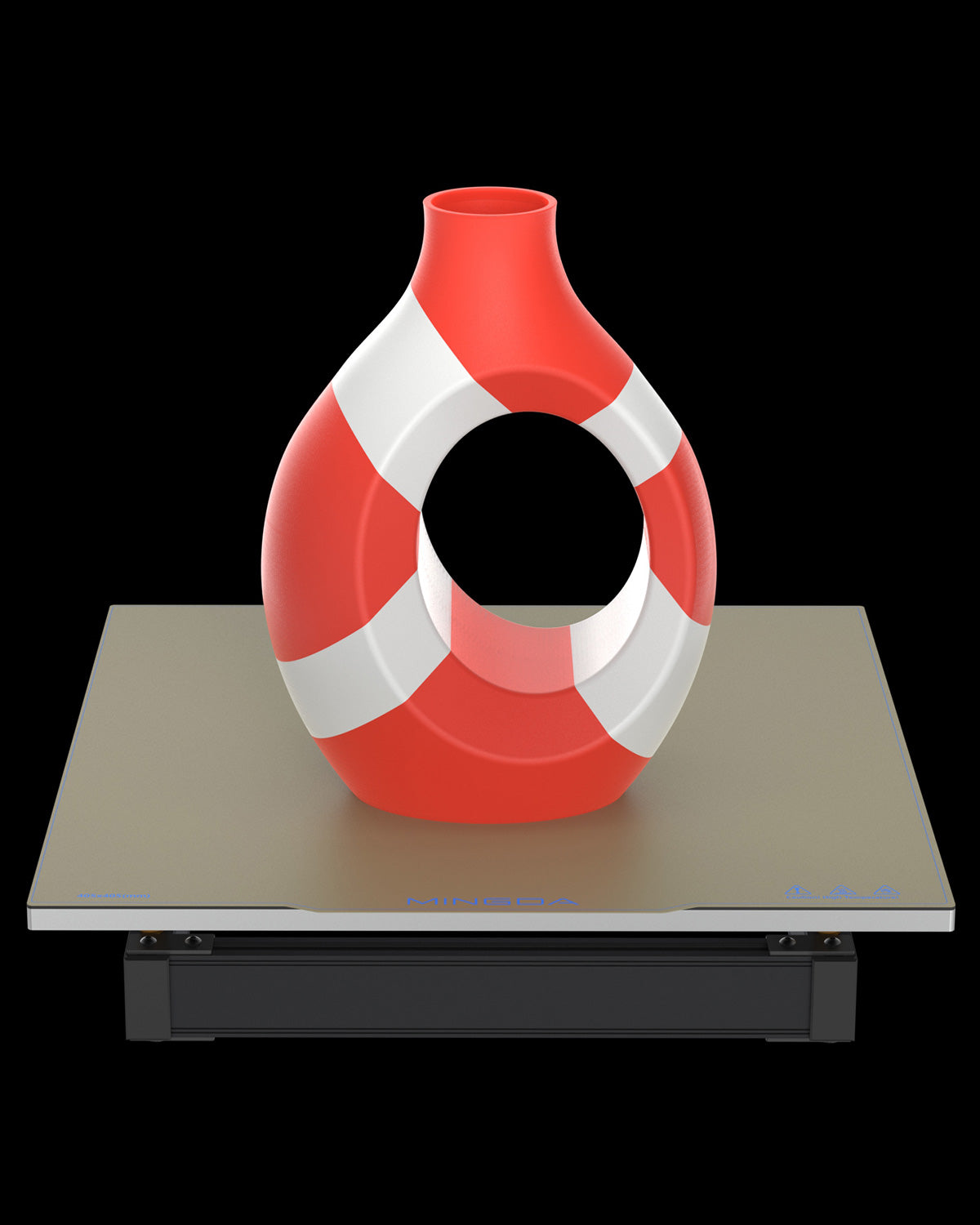

Soluble Support Filament

Printing complex models with internal geometries and hollow structures is made possible by using water-soluble filament.

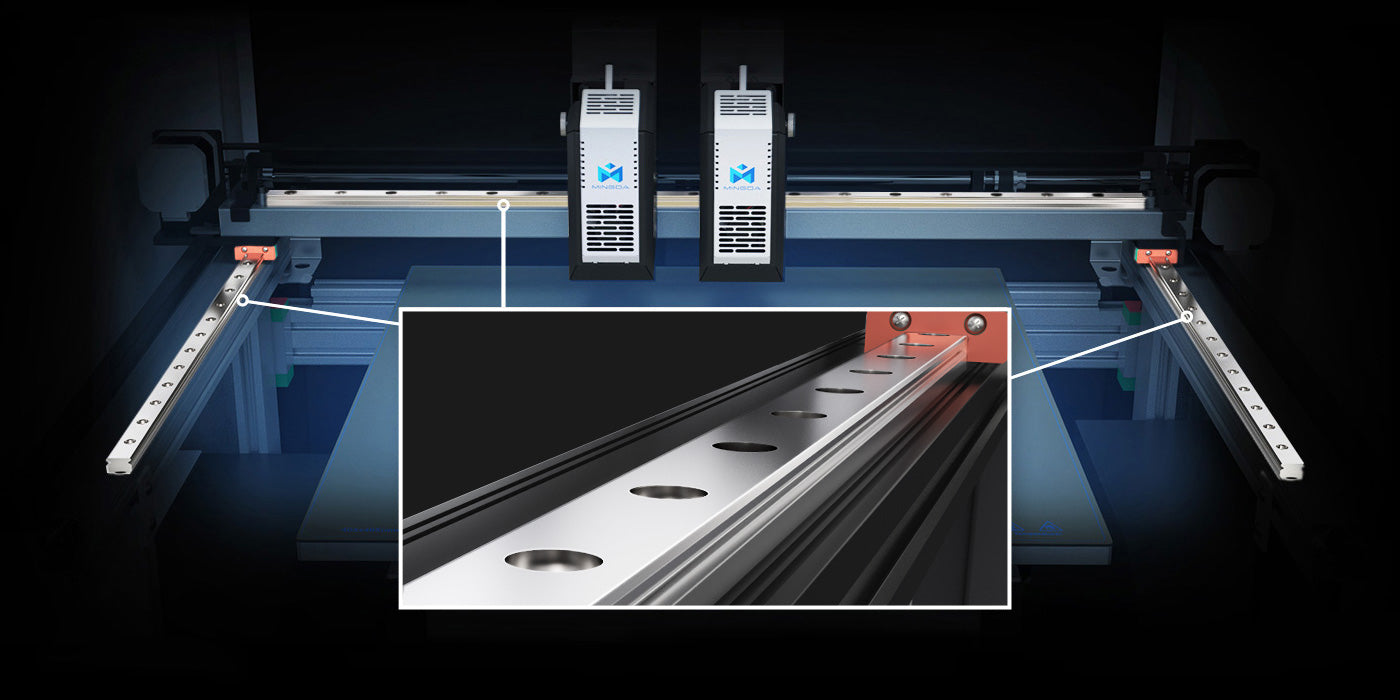

High-precision Linear Rails

The industrial-grade linear rails are made by CNC grinding at the micron level, ensuring smooth and steady movements. A significant rise in precision, rigidity, and durability for you to savor a fast, accurate, and steady making experience.

Vibration Compensation

Input Shaping reduces mechanical vibration by adjusting input signals.It

enhances stability and performance which is the key to fast printing.

Max temperature of hotend is 350°C

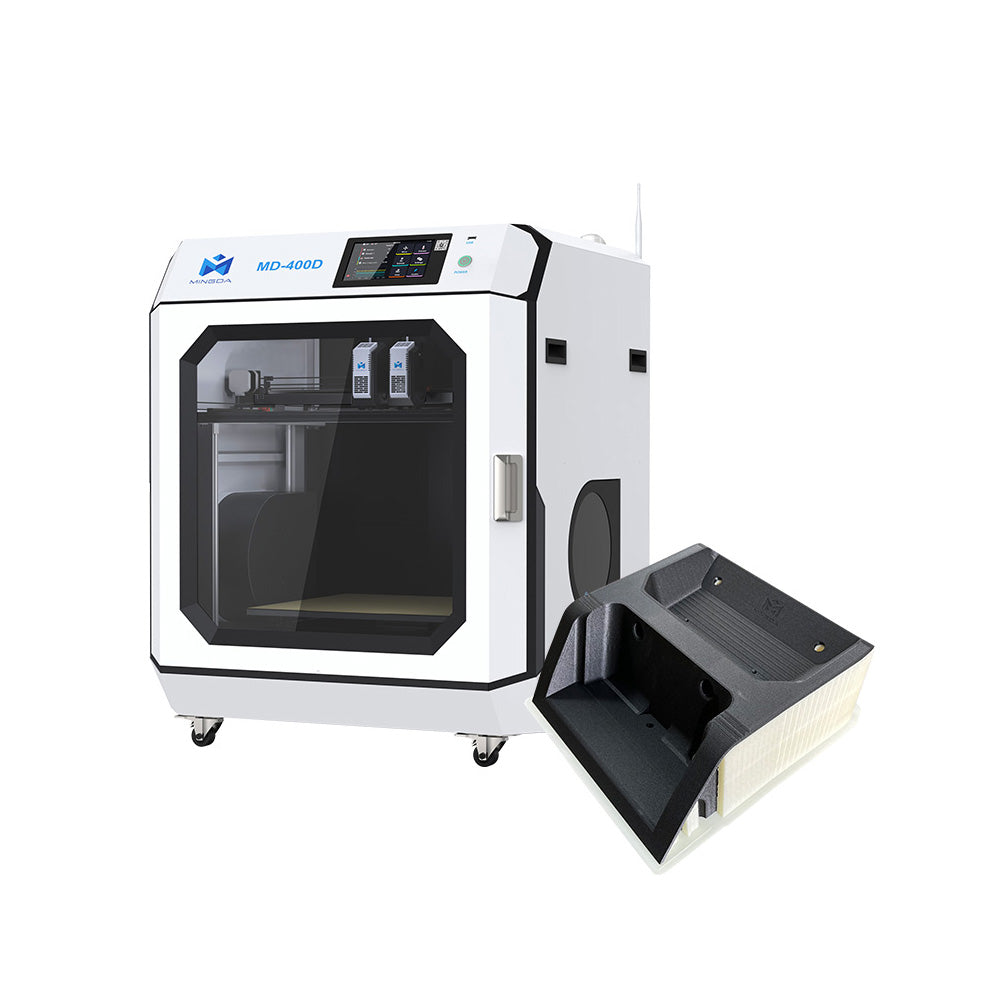

Innovative IDEX Calibration

Hands-free Auto Leveling

The automatic leveling system greatly improves printing efficiency and quality stability. It helps to reduce failed prints caused by an unleveled build plate. The precise calibration of nozzle distance also enables 3D printers to print models with finer layer resolution.

XY Axis Offset Calibration

Fine-tune the XY axis to align the nozzle center of the right extruder with the origin of the XY axis.

Z Axis Offset Calibration

Fine-tune the Z axis to align the nozzle center of the right extruder with the origin of the Z axis.

Remote Printing Multi-Machine Control

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.

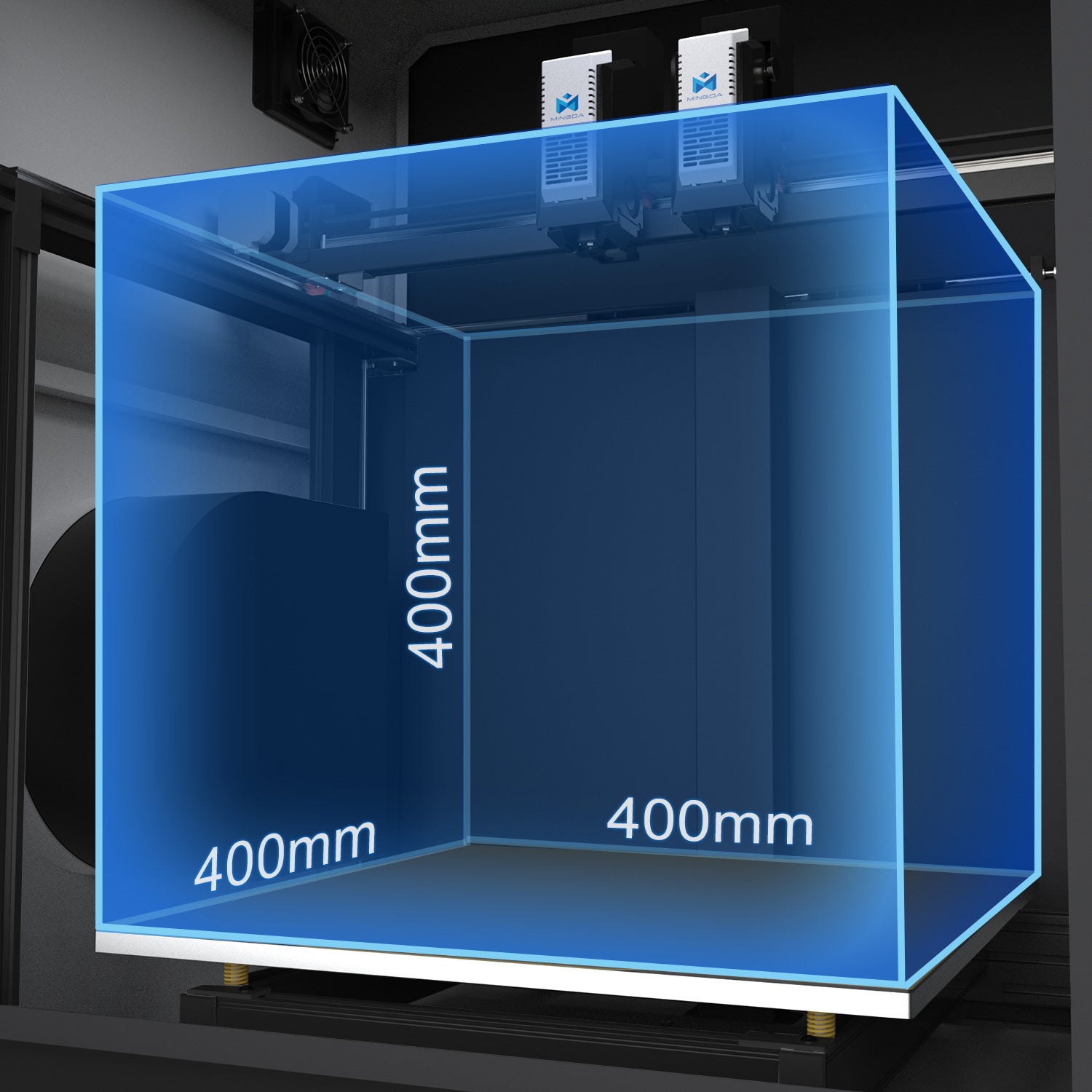

Large Build Volume

Printing size: 400mm*400mm*400mm;

meets most prototype printing needs

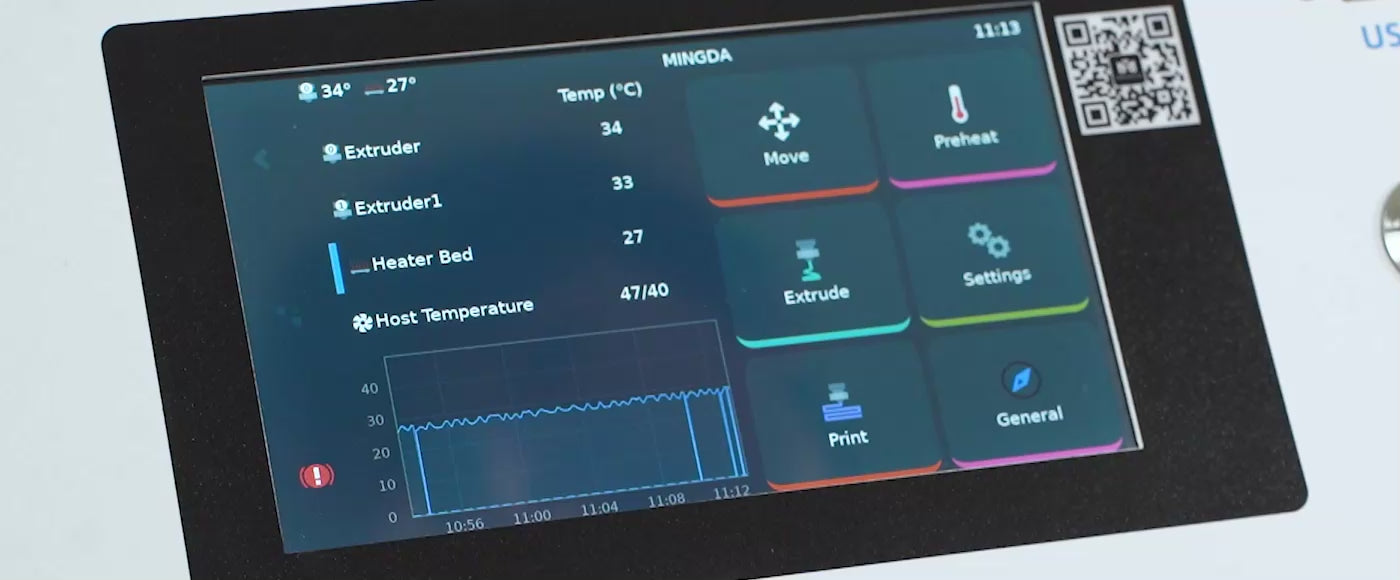

7-inch IPS High-definition Large Screen

MD-400D has a 7-inch IPS high-definition computer screen. Compared with traditional LCD screens, it can see bright, saturated, and natural high-quality images from any angle. At the same time, it is more environmentally friendly and saves electricity.

Double protection to prevent accidents during the 3D printing process, thereby avoiding model printing failures.

Smart Resume Printing Function

The printer will automatically remember its current position and save printing data. In the event of a sudden power outage, it will lower the platform and retract the filament. Upon power restoration, it will resume seamless printing from the last stopping point.

Automatic Filament Detection

When filament runs out, the printer will stop printing and issue a warning to replace the filament, preventing wasted prints.

MD-400D

Fused Deposition Modeling (FDM)

400 * 400 * 400 mm

400(2*200)*400*400 mm

320(2*160)*400*400 mm

690 * 790 * 910 mm

Two

0.4mm (0.6, 0.8, 1.0 mm optional)

≤350°C (Recommended temperature ≤320 ℃)

≤110°C

40mm³/s

500mm/s (Recommend Printing Speed: 200-300mm/s )

MingDa OrcaSlicer, Prusa Slicer, etc

7-inch HDMI touch screen

100/240AC 50/60Hz

800W

klipper

Common filament: PLA, TPU, PETG;

Engineering filament: PA-CF/GF, PET-CF/GF, HtPA-CF/GF, ABS-GF25, ABS-CF20, PA-GF25/CF25;

Support filament:S-Mulit, S-HtPA, PVA, etc

Service

MINGDA Slicer

Manual

Video Tutorials